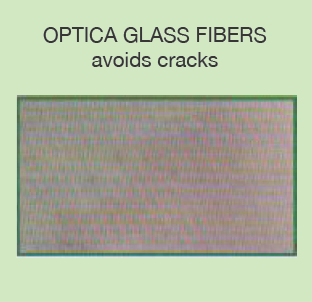

OPTICAFIBERS A MULTIFILAMENT GLASS FIBER WITH ENGINEERING PROPERTIES. MILLIONS OF MONO FIBERS GET UNIFORMLY DISPERSE IN EVERY CUBIC METER OF CONCRETE / MORTAR AND DEVELOP MICRO SECONDARY REINFORCEMENT (MSR) SYSTEM.

| Description | OPTICAFIBERS | POLYESTER | POLYPROPYLENE |

| Number of Fibers | 132 million / m3 | 108 million / m3 | 13.5 million / m3 |

| Description | OPTICA GLASS FIBER | POLYESTER | POLYPROPYLENE |

| Number of Fibers | 132 million / m3 | 108 million / m3 | 13.5 million / m3 |

| Tensile Strength | 1700mpa (250KSI) | 550mpa (80KSI) | 400mpa (60KSI) |

| Dosage | 600 gms / m3 85 gms / Bag |

900 gms / m3 125 gms/ Bag |

900 Gms / m3 125 gms / Gag |

| Dispersion | High Dispersion | Float up and form bunches | Float up and form bunches |

| Softening Point | 775 C | 230 C | 150 C |

| Elongation at break | 2.4 % | 15% | 20% |

| Combustibility | Non Combustible | Combustible | Combustible |

Optica Glass Fibers Use methodology: RMC - After mixing of cement, sand, blue metal in the RMC Plant, add 600 grams (one pouch) 12mm Optica Glass Fibers along with the mixed concrete.

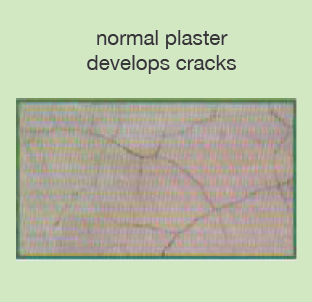

Each fiber disperse uniformly mix in between the blue metal, sand and cement thus allows different materials to expand and contracts independently during different weather conditions and avoid frictions between the materials which helps avoid cracks within the concrete.

10 times more Glass fibers then any other types of fibers per cubic meter. Optica Glass Fibers has higher tensile strength, strong enough to avoid breakages while in operation in RMC plant up to pouring of concrete at the site.

Integral water proofing chemical is not required as OPTICA Glass fiber will take care of preventing hairline cracks, thus arresting of expanding to a larger cracks over a period of time, which helps prevent seepage for life.